Hydrogen Wave 2040 to push renewable energy agenda with hydrogen-powered products and technologies

Hyundai Motor Group announced their plans for a sustainable future through hydrogen-fuelled products and technologies. This was shared through Hydrogen Wave 2040, an online forum.

The plans include:

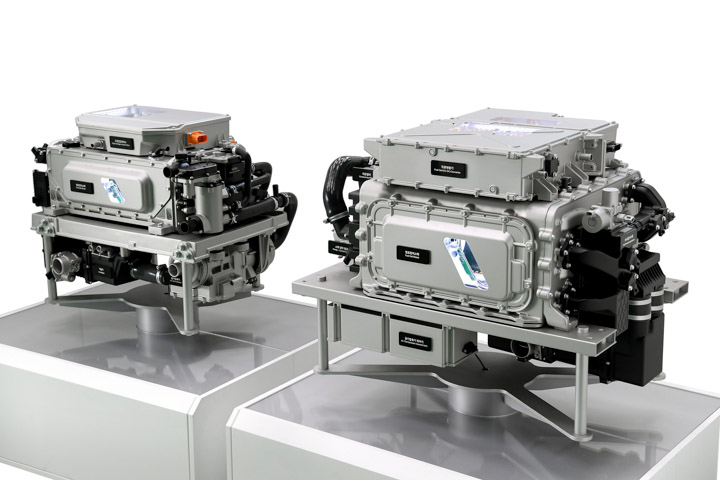

- introducing a next- generation fuel cell system in 100kW and 200kW variations by 2023 with costs being lowered by more than 50%, while the total package volume is reduced by 30% and power output doubled

- Hyundai Group to become the first automaker to apply fuel cell systems to all commercial vehicle models by 2028

- achieve a fuel cell electric vehicle (FCEV) price point comparable to a battery electric vehicle (BEV) by 2030

- apply fuel cell systems to all types of mobility and furthering the technology to include homes, buildings and powerplants as energy solutions

Hyundai Group also shared future concepts featuring fuel cell technologies that we can look forward to:

- Trailer Drone

- high-performance sports car

- fuel cell equipped vehicles for emergency relief and rescue missions

Hyundai Group developed its first Fuel Cell Energy-Efficient Vehicle (FCEV) in 1998 and has since introduced several hydrogen-powered vehicles including the Tucson FCEV (ix35 Fuel Cell) in 2013, the Nexo SUV in 2018 and the Xcient Fuel Cell, the world’s first heavy-duty fuel cell truck in 2020.

The Group is also developing a five- to seven-metre fuel cell purpose-built vehicle for the global light commercial vehicle market which is projected to be seven million unit sales in 2030.

The potential for fuel cells and fuel cell systems extends to high-performance vehicles, urban air mobility, robots, aircrafts and large ships as well as non-transport applications – the provision of electricity and heating to buildings, urban energy sources and power plants.

Hyundai Group will push economies of scale to increase volume and bring down the cost of production while also improving durability and output. They will also develop higher capacity fuel cells with higher output, as well as develop refuelling infrastructure and portable hydrogen refuelling facilities to make adoption of hydrogen fuel cell system more convenient and efficient.

The table below outlines all mobility and fuel cell systems presented in today’s Hydrogen Wave online global forum:

| Name | Specification (Length x Width x Height) | Key Features |

| M.Vision POP | 2,600×1,644×1540mm | EV-based ultra-small urban mobility vehicle e-corner module for in-place turning, crab-drive and automatic parallel parking |

| M.Vision 2GO | 3,200×1,644×1600mm | FCEV-based near-range delivery mobility 30kW fuel cell battery pack |

| NEXO Minicar | 1,180×700×550mm | FCEV minicar for children |

| XCIENT Fuel Cell | 9,745×2,550×3,730mm | World’s first mass-produced fuel cell truck |

| XCIENT Fuel Cell Tractor | 8,701×2,585×4,060mm | Currently in-development based on the XCIENT Fuel Cell Truck 12-month pilot service in California (August, 2021 – July, 2022) |

| Fuel Cell Electric Tram | 21m×2.45m×3.4m | Battery and fuel cell hybrid power sources |

| Mobile Fuel Cell Generator | 2,850×1,550×1,225mm | Supplied to the world’s first all-electric touring car race series, the ETCR |

| Hydrogen Fuel Cell Powerpacks (30kW and 50kW) | [30kW] 680 x 820 x 620mm [50kW] 852 x 1025 x 784mm | Powerpacks for forklifts and excavators |

Trailer Drone

The Trailer Drone concept is a purpose-developed hydrogen-powered container transportation system capable of operating fully autonomously. The Trailer Drone would have a range of more than 1,000km from a single charge, comparable to existing container transportation systems.

The autonomous capabilities of the Trailer Drone were developed according to the specific requirements of a container transporter and the way container terminals operate which meant that engineering teams from the Group needed to completely redefine how a container manoeuvres. As a result, the engineering team developed the ‘Fuel Cell e-Bogie’.

Fuel Cell e-Bogie

The term ‘bogie’ comes from the rail industry. Rail bogies are wheel subframes that sit under every train car. The Fuel Cell e-Bogie sits under the container just like a rail bogie and is a fully enclosed system with fuel cell propulsion and fully-independent four-wheel steering. The Trailer Drone concept requires two fuel cell e-Bogies which would enable considerable sideways manoeuvrability. The Trailer Drone can move autonomously through portside operations and tight urban environments. There is ‘Cluster Mode’ which enables multiple Trailer Drones to travel together in an almost train-like configuration.

The Fuel Cell e-Bogie is not exclusive to the Trailer Drone and has other applications in a wide value chain such as ground logistics, construction, firefighting and disaster relief missions. It offers a multi-purpose platform, capable of a variety of objectives – all in zero-emission and autonomous operation.

Vision FK

Fuel cell technology also has a role in high-performance vehicles. The Group has showcased a concept hydrogen-powered hybrid sports car, named the Vision FK. It has a maximum output of over 500kW and accelerate from 0-100km/h in less than four seconds. Combining a fuel cell energy converter with a high-power, RWD, plug-in powertrain, the Vision FK aims to achieve over 600km in range.

Rescue Drone

The Rescue Drone is a flying drone with a Fuel Cell e-Bogie which can be operated remotely and autonomously for critical operations such as fire-fighting and life-saving. The Rescue Drone features an independent steering system for in-place turning manoeuvres and ‘crab-walk’ driving. It can also carry out missions via images transmitted from drones mounted on the vehicle exterior and achieves a 450 to 500km driving range from a single charge.

H Moving Station

The H Moving Station is a heavy-duty vehicle equipped with charging facilities for FCEVs. This portable hydrogen refuelling station ensures convenience as well as charging options in areas with limited hydrogen refuelling stations.

RHGV (Rescue Hydrogen Generator Vehicle)

The RHGV supplies power to vehicles in remote, off-road areas. The portable electric vehicle charger offers single-phase 220V and 3-phase 380V simultaneous power supply.